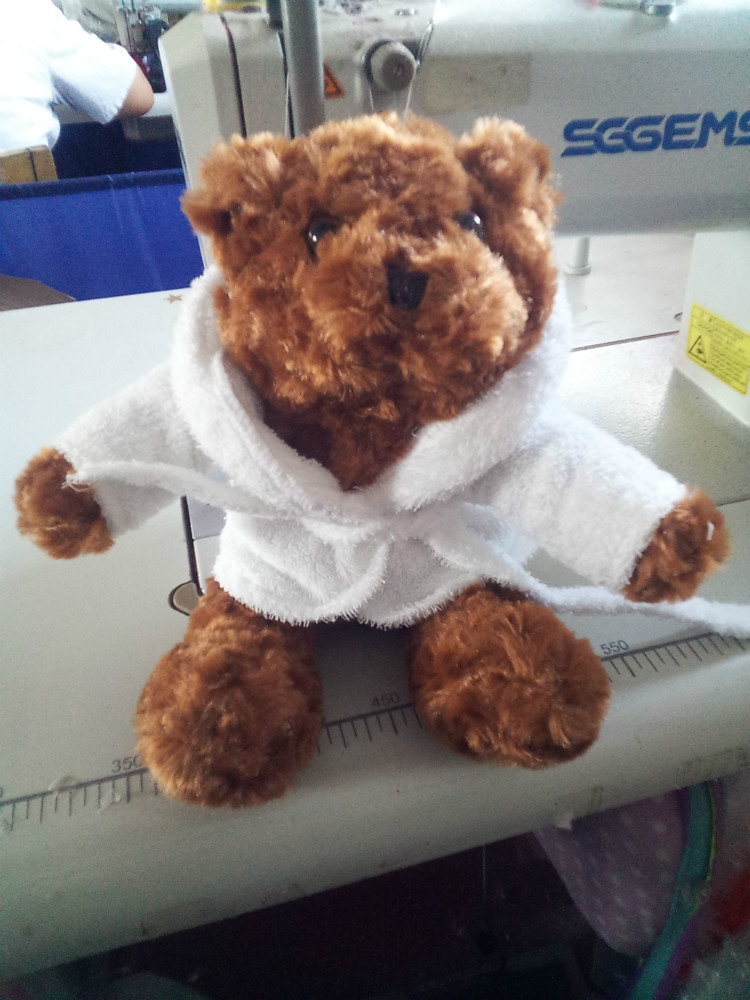

Plush animal door stopper, plush toys and some Hot water bottle covers are very similar in appearance, except for the internal filling. Sea sand is now popular in doorstops as a filler.

Toys made through a series of processes with various chemical fibers, pure cotton, T/C, non-woven fabrics, leather, plush, short fleece and other materials. Process: Shape Design-Proofing-Typesetting-Tailoring-Sewing-Assembly-Filling-Binding-Shaping-Forming-Needle Detection-Packaging 2. The main process content of fabric plush toy manufacturing (1) Appearance design and proofing: first, the design department or the sample submitted by the customer is handed over to the mold cutting workshop to make the mold and blank. (2) The machinist sews on the machine. The main tasks are: sewing the main body, applying the cloth label, and sewing additional accessories. (3) Install the exclusive accessories of the cloth plush toy (4) Fill the individual and the whole of the cloth plush toy with cotton (5) Manually stitch the cotton filling mouth, reshape and hang the thread (6) Detect whether there is metal in the cloth plush toy Keep things to ensure the safety of the cloth plush toys (7) Pack the cloth plush toys and then shipping.

Fabric for plush toys

1. Plush cloth: A, A yarn (also called ordinary yarn, BOA material), divided into: shiny yarn: ordinary generally shiny, under the light, the hair direction can be divided into yin and yang. Matte yarn: it is matte, basically without yin and yang. B. V yarn (also called special yarn, T-590, Vonnel) has EvenCut and Unevencut. The hair length is in the range of 4-20mm, which is a mid-range material; C, Hi-pile: wool The length is in the range of 20-120mm, and any hair length can be made within the range of 20-45mm, and only 65mm and 120 (110) mm above 45mm are long and short hairs. D. Others: 1. Tumbling boa and A yarn. Curly hair: mostly granular hair, lamb hair, or hair roots are bundled and rolled up. Usually used to make more classical toys, the hair length can be up to 15mm; the price is much cheaper than the Hi-pie style curls. b.Tumbling H.P, Haipai Curl: Usually the hair is longer, the curling effect is looser, and there are many styles to choose from; 2. Super soft material: has been used, the material is very soft; the price of the original yarn is different. 3. There is also D.D.F: It is a kind of H.P., hard straight, high-grade material, usually mixed colors. E. Plush printing materials include: 1. printing, 2. jacquard, 3. tip-dyed, 4. variegated color, 5. two tone, etc.

2. Velboa: The softness of the wool surface, generally the wool is down, and the quality is poor.

3. Velour (velour): similar to shearing cloth, but the hair length is about 1.5-2mm, and the elasticity is larger than that of shearing cloth; there is no wool direction.

4. Edge Lun Fabric (Nylex, Tricot): It is divided into ordinary edge Lun cloth (100% Polyster) and Nylon edge Lun cloth (Nylon), and the common type is usually used. It is easy to make, cut pieces and silk screen, and embroider. In the case of cut pieces and silk screen, you must control the hair length of the fetching hair not to grow (usually no more than 1mm), otherwise the silk screen will be difficult, the color will not penetrate easily, and the color will fade easily.

5. T/C cloth: (the composition is 65% Polyster, 35% Cotton) is divided into three types: 110X76: thicker, used in printed cloth or products with higher requirements; (higher density, not easy to spread) 96X72 The density is thinner. 88X64 has a loose structure, so the order is usually made of medium and light pulp, so as to avoid the seam easily scattered and cause burst.

6. Cotton cloth (100% Cotton): used to make higher-grade printed cloth, which is thicker than T/C cloth.

7. Felt cloth (Felt): Pay attention to the thickness and flexibility. It is divided into ordinary polyester and acrylic. We usually use ordinary polyester, which is harder and has a thickness of about 1.5mm. The acrylic is very soft, and the tissue is loose and easy to rot , Often used in gifts, less used in toys.

8. Polar fleece is divided into single-sided fleece and double-sided fleece. It has a soft hand feeling but greater elasticity.

9. PU leather: It is a kind of Polyester, not genuine leather. Note that the thickness of the fabric varies depending on the base fabric. (Note: PVC materials cannot be used in all toys at present, because PVC contains excessive toxic and fatal elements, so please pay attention to the material not being PVC in nature.)

10. Twill cloth (Heavier T/C): Cotton or T/C: thicker, the grain is clearly visible.

11. Zheshi cloth: measure the texture according to the count; choose according to the grade and purpose of the product.

12. Knitted fabric: According to the gram weight, the quality is divided into cotton or T/C. The fabric has greater elasticity.

13. Electronic cashmere: thinner and brighter, but the wool surface is not soft enough;

14. Velvet: There are several grades. The difference from electronic velvet is that it is softer and relatively expensive.

15. Flocking Material: It is divided into single-sided and double-sided. If the base fabric is different, the thickness and hardness are different, and the price is also different.

16. Satin: usually it is not easy to sew, it is too soft and easy to run yarn;

17. Nylon cloth: lining cloth: 170T, a kind of nylon cloth. It is very thin and cheap. You can consider making the inner bag lining: ordinary nylon cloth: 190T: thick nylon cloth: 210T: Oxford cloth: 420T or more.

18. Washable cloth and wrinkle cloth (Nylon Taffeta): The cloth surface has wrinkles, because it can be washed with water, some products will be used, but it is not easy to sew).

19. Terry cloth: Cotton: The loops are relatively high and appear rough. Use a thick and dense base cloth for toys to make the cotton difficult to escape. T/C type: The loops are fine and smooth. They are mostly used in baby products, bath products, etc. Pay attention to the thickness of the base fabric and not penetrate cotton.

20. Others: denim, flashing cloth.

Stuffing for cloth plush toys

1. Making surplus waste (sub): It is a recycled cotton textile used as a substitute for kapok filler that was short of after World War II. This cotton filler is made of wool and cotton scraps and surplus of cotton products It is composed of thread balls and hair balls. The darker the composite, the lower the color. Synthetic textile waste from the 1860s was also used for filling.

2. Acrylic fiber: Invented by DuPont in 1950, it is composed of acrylonitrile, containing more than 85% is called acrylic, and 35%~85% is called modacrylic. The appearance is round or eight-shaped, the surface is smooth, it is not easy to absorb water, it is resistant to acid, alkali and sunlight, and it is not easy to turn yellow. It is the beginning of a new era and the diversification of raging cilia.

3. Darclon: The filling material is also a kind of polyester fiber, invented by DuPont in 1953.

4. High-quality shavings (excelsior): excelsior means high-level in Latin, so in order to prove that the quality ingredients are very good, the label will indicate "excelsior". In the nineteenth century, kapok shavings and fine planed wood shavings were originally used for decorative filling, but later they were used for flaming filling.

5. Fiber Fill: Taken from white polyester fiber, it is a very soft filling waste. The United States calls it Darclon, and Taiwan calls it polyester cotton.

6. Foan-rubber: Refined polyurewthare, which is a kind of artificial sponge, processed from a model. It was originally used to fill furniture and decorations. It has excellent softness and plasticity and is similar Mute cotton orange sponge.

7.kapok: It is a kind of tree, taken from the single cell that grows in the seed pod, about one inch in length, white or yellowish brown, with silky luster, waterproof, light weight, elastic, smooth, It is soft, flammable and easy to store. It is a material from Malayan, which has been used since the 18th century

8. Oil clothe: also known as leather cloth. Because this kind of leather is post-processed, it is a kind of waterproof cloth, and it was used as a package for toy bear speakers in the early days.

9. Polyester fiber: It is a synthetic fiber extracted from petroleum. It is usually woven with silk made from natural synthetic fibers. It is a combination of at least 85% dihydric alclhol and terephthalic acid in a round shape. , Smooth surface, good elasticity, easy to wash and dry, with good thermoplasticity.

10. Polystyrene pellets (polystyrene): Invented in Germany in 1929, it was the first synthetic plastic to be used. It was used as a filler after World War II. It is a strong and very lightweight foam pellet. small ball.

11. Woven waste (sub): In foreign countries, sub is the general term for filling waste, and the content includes cotton waste and man-made fiber waste. These are not like Polyester fiber and fiber fill are like artificial cotton. Its disadvantages are that it is not easy to clean, difficult to store and easy to mold.

12. Wood-wool: It is a kind of soft, long strip of high-quality shavings cork. It was originally used to pack stuffing for furnishings, but in the bear world, it is generally used as a copy of bear and Traditional handmade bear stuffing. After filling, the bear feels more solid, full and full of toughness, but you must use a wooden stick when filling, otherwise it will stab your hands.

Other ingredients for toys

The ingredients for toys include:

1. Eyes

2. Nose

3. Ribbon

4. Tape

5. Carton

6. Cotton

7. Rubber particles

8. Plastic ingredients

9. Printed matter

10. Cloth label, woven label

11. All kinds of color matching cotton belts, webbing, silk cords, and elastic

12. Velcro, buckles, zippers

Contact: Bin Li

Phone: 86 15189700574

Email: li@bofatetrading.com

Add: No. 5, Zhuxianghe Road, Shiqiao Town Industrial Park, Economic Development Zone, Yangzhou, Jiangsu, China

We chat